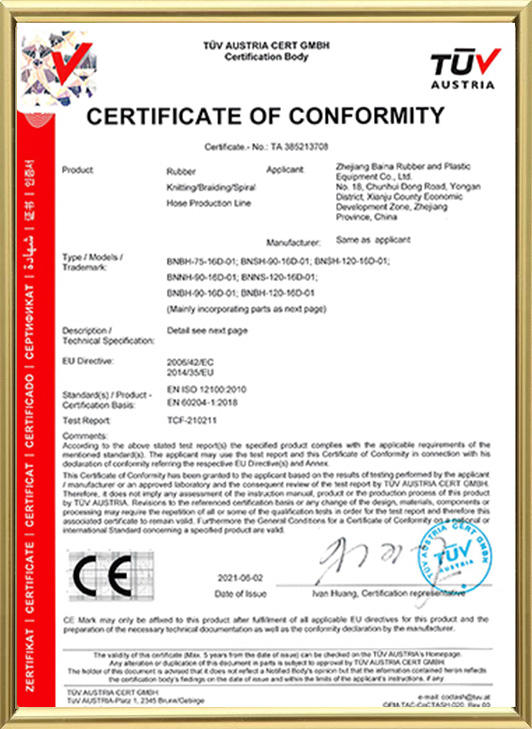

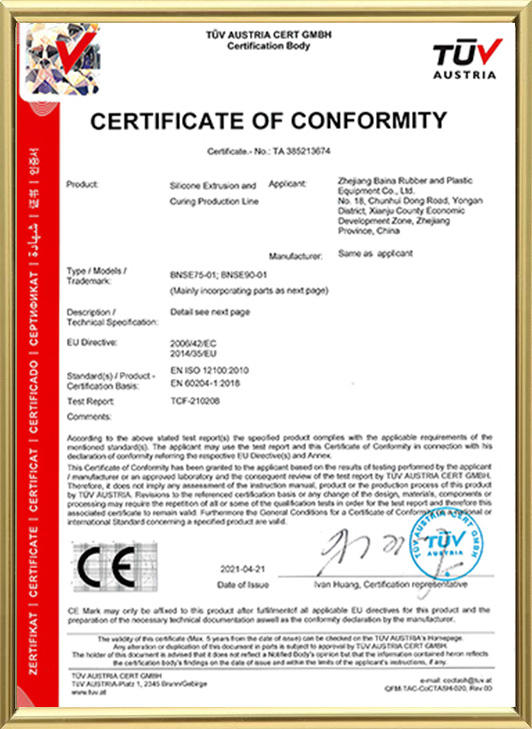

- Production Line Series

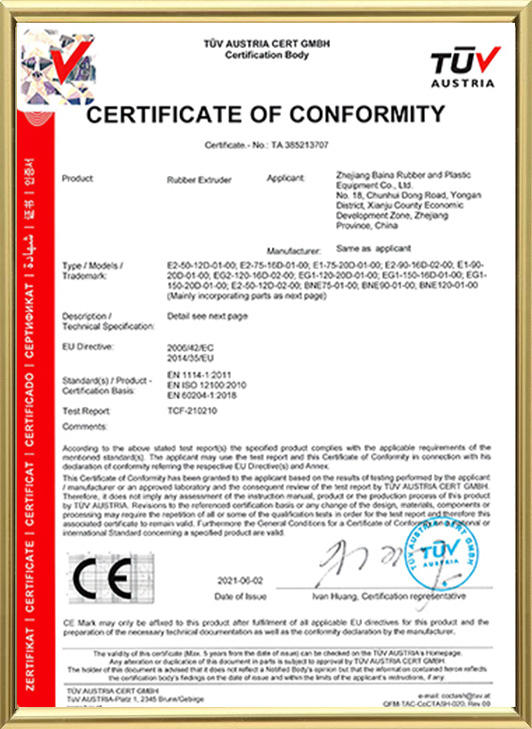

- Rubber Extruders Series

- Auxiliary Equipment Series

- Environmental Protection Series

We’re a reliable partner that shapes our expertise into success for your project.

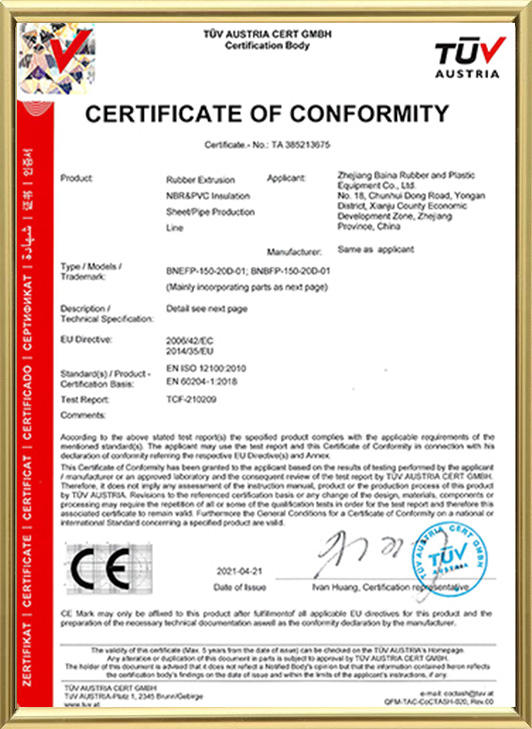

Contact UsNBR & PVC A/C Insulation Sheet/Pipe Production Line

Zhejiang Baina Rubber & Plastic Equipment Co., Ltd. was established in 1998 with a total investment of 120 million RMB. It is a high-tech enterprise specializing in the production of rubber and plastic machinery complete sets of equipment and rubber products, Zhejiang Science and Technology SMEs, and municipal innovation pilot enterprises. The company is located in Xianju County Modern Industrial Park, which covers an area of 90 acres and, construction area of more than 80,000 square meters. The company is adjacent to 35 Provincial Highway and Taijin Expressway, and the traffic is very convenient.

FROM THE BLOG

Here to find the latest company and industry news and learn more professional product knowledge.

English

English