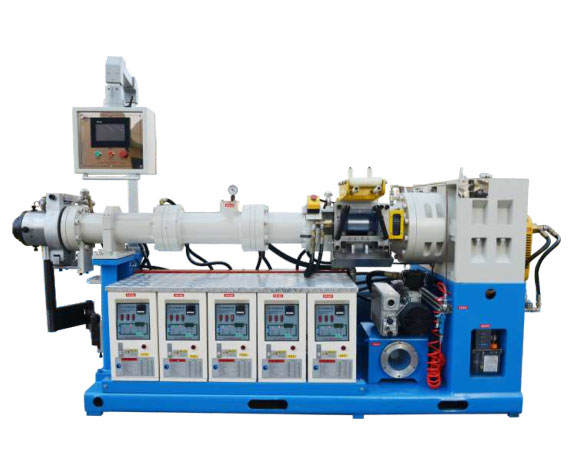

Main Elements of A Rubber Extruder

A rubber extruder has two main elements. These are the cold end and hot end. The cold end refers to the upper portion of the 3D printer extruder system where the filament is fed. On the contrary, the hot end is where the filament gets melted and squirted out. Cold endThe cold end consists of stepper...

English

English 中文简体

中文简体 русский

русский