The Complete Rubber Extrusion Production Line: Key Components and Their Functions

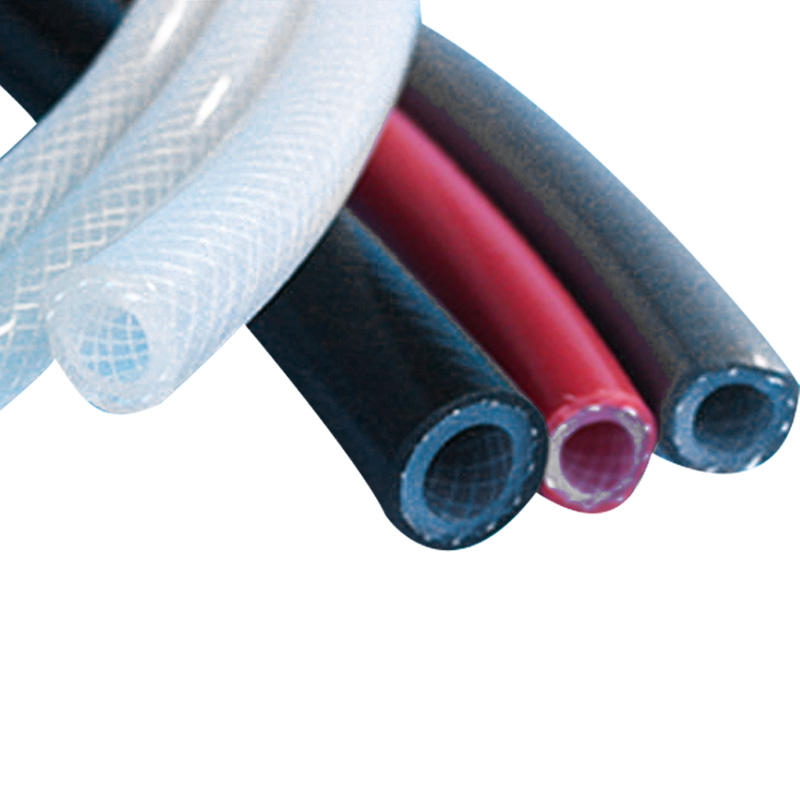

The rubber extrusion production line plays a crucial role in modern manufacturing, particularly in industries that require the production of rubber products, such as automotive components, seals, gaskets, hoses, and many others. A rubber extrusion line is an integrated system that processes raw rubb...

English

English 中文简体

中文简体 русский

русский