-

50mm12D Rubber Extrude Machine: Enhancing Efficiency and Precision in Rubber Processing

1. Precision and Control One of the primary advantages of the 50mm12D Rubber Extrude Machine is its high level of precision and control in t...

-

The 5th GBA International Exhibition on Rubber and Plastic Technology, Baina Will Attend The Event With You!

Exhibition date: May 15-17, 2025Exhibition number: A471Exhibition address: Hall 20.2, Zone D, China Import and Export Fair Complex, Guangzho...

-

The Capabilities of the 90mm Silicone Extrude Machine

Supply 90mm Silicone Extrude Machine Exporter Producer The 90mm silicone extrude machine is an essential piece of equipment in industries wh...

-

90mm Silicone Extrude Machine: A Journey Through Innovation and Industry

90mm Silicone Extrude Machine Manufacturing in China To understand the role of the 90mm silicone extrude machine, it's crucial to explore th...

- Production Line Series

- Rubber Extruders Series

- Auxiliary Equipment Series

- Environmental Protection Series

We’re a reliable partner that shapes our expertise into success for your project.

Contact UsRubber Extrusion Production Line Factory

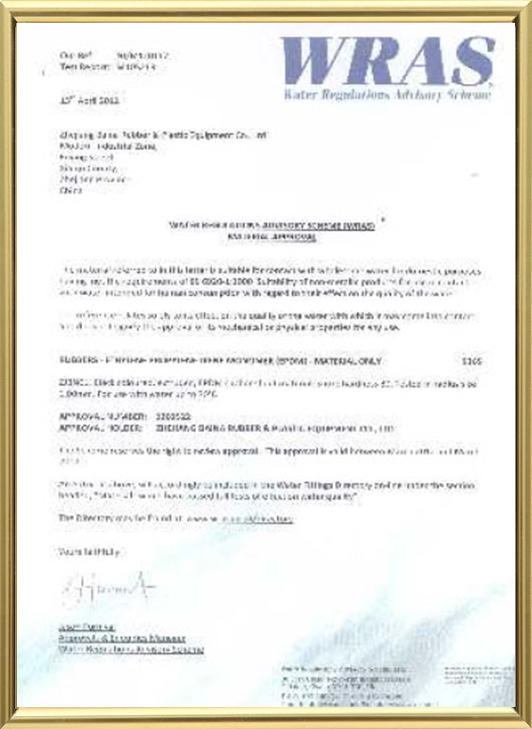

Established in 1998 with a total investment of 120 million RMB, Zhejiang Baina Rubber & Plastic Equipment Co., Ltd is a China Rubber Extrusion And Microwave Curing Production Line Manufacturer and Rubber Extrusion And Microwave Curing Production Line Factory, and it is also Zhejiang Science and Technology SMEs, and municipal innovation pilot enterprises. The company is located in Modern Industrial Park of Xianju County, which covers an area of 90 acres and a construction area of more than 80,000 square meters. It is also conveniently located adjacent to the 35 Provincial Highway and the Taijin Expressway.

FROM THE BLOG

Find the company and industry news and learn more professional product knowledge.

Rubber Extrusion And Microwave Curing Production Line Maintenance Attention

Rubber extrusion and microwave curing production line maintenance are important to ensure the smooth and efficient operation of the equipment and to prevent breakdowns and production delays. Some of the maintenance attention that should be given to these production lines are:

Regular cleaning: The production lines should be cleaned regularly to remove any debris, dust, or other contaminants that may accumulate on the equipment. This will help prevent any damage to the equipment and ensure the quality of the products.

Lubrication: The moving parts of the equipment should be lubricated regularly to reduce friction and prevent wear and tear. This will help extend the lifespan of the equipment and ensure smooth operation.

Calibration: The equipment should be calibrated regularly to ensure that it is operating at the correct settings and producing products that meet the required specifications.

Inspection of belts and chains: The belts and chains of the equipment should be inspected regularly to ensure that they are in good condition and properly tensioned. Any signs of wear or damage should be addressed immediately to prevent breakdowns and production delays.

Replacement of worn parts: Any worn or damaged parts of the equipment should be replaced promptly to prevent further damage to the equipment and ensure the quality of the products.

Regular maintenance of microwave generators: The microwave generators used in the curing process should be inspected and maintained regularly to ensure they are operating correctly and efficiently.

Regular maintenance and attention to detail are crucial in ensuring the smooth and efficient operation of rubber extrusion and microwave curing production lines. Proper maintenance will help prevent breakdowns, improve the lifespan of the equipment, and ensure the quality and consistency of the products.

Types Of Rubber Extrusion Curing Production Line

Rubber extrusion curing production lines are designed to cure or vulcanize rubber extrusions to improve their strength, durability, and other properties. There are several types of rubber extrusion curing production lines available in the market, each with its own unique features and benefits. Some of the common types of rubber extrusion curing production lines include:

Microwave curing production line: This type of production line uses microwave technology to cure rubber extrusions quickly and efficiently. Microwave curing production lines are ideal for high-volume production facilities that require fast curing times and high productivity.

Hot air curing production line: This type of production line uses hot air to cure rubber extrusions. The extrusions are passed through a chamber with heated air, which causes the rubber to cure and vulcanize. Hot air curing production lines are suitable for small to medium-volume production facilities.

Infrared curing production line: This type of production line uses infrared radiation to cure rubber extrusions. The extrusions are passed through a chamber with infrared lamps, which emit heat that causes the rubber to cure and vulcanize. Infrared curing production lines are ideal for high-quality rubber products that require precise curing.

Steam curing production line: This type of production line uses steam to cure rubber extrusions. The extrusions are passed through a chamber filled with steam, which causes the rubber to cure and vulcanize. Steam curing production lines are ideal for large-scale production facilities that require high-quality rubber products.

Salt bath curing production line: This type of production line uses a salt bath to cure rubber extrusions. The extrusions are passed through a bath of molten salt, which causes the rubber to cure and vulcanize. Salt bath curing production lines are ideal for the high-temperature curing of rubber products that require excellent resistance to heat and chemicals.

The choice of rubber extrusion curing production line will depend on the specific needs and requirements of the production facility, including the volume of production, quality requirements, curing time, and other factors.

English

English 中文简体

中文简体 русский

русский