-

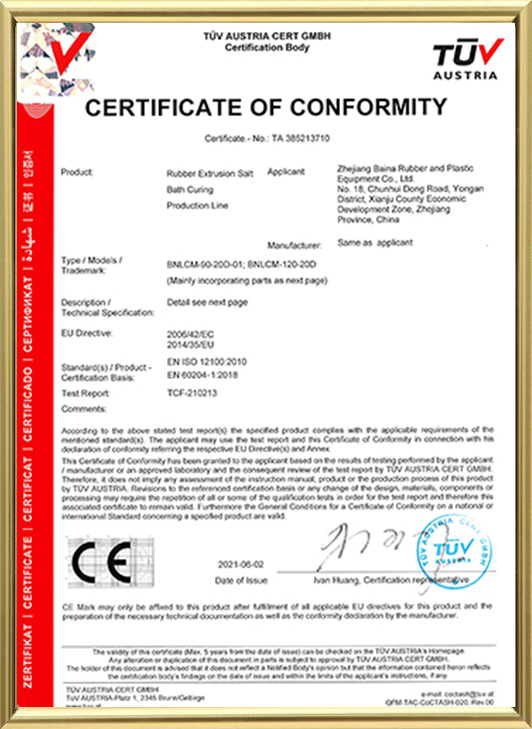

Common Uses of a Salt Bath Curing Line

Salt bath curing is a heat treatment process used to enhance the properties of various materials, particularly metals. I...

-

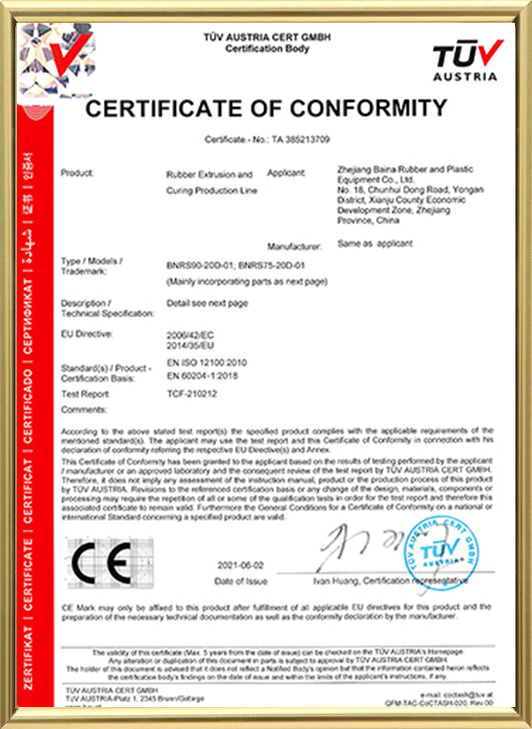

Understanding the Rubber Extrusion Production Line

The rubber extrusion production line is a key component in the manufacturing of various rubber products. This process is...

-

The Integrated Rubber Extrusion Production Line

The transformation of raw rubber compound into a finished, cured profile is not accomplished by a single machine but by ...

- Production Line Series

- Rubber Extruders Series

- Auxiliary Equipment Series

- Environmental Protection Series

We’re a reliable partner that shapes our expertise into success for your project.

Contact UsRubber Single Extrusion And Microwave Curing Production Line

Contact Us Email: [email protected]

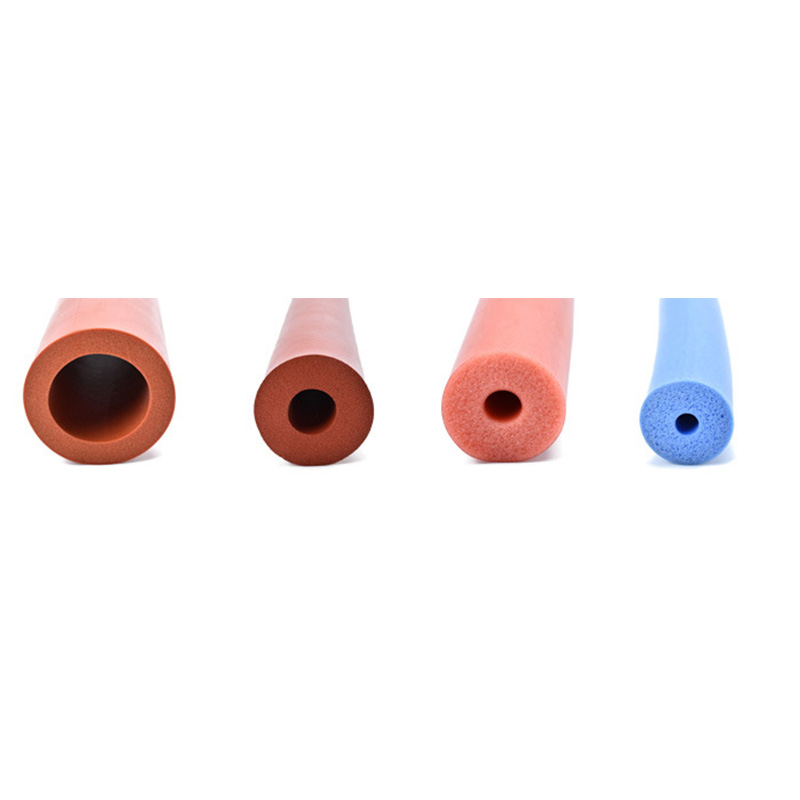

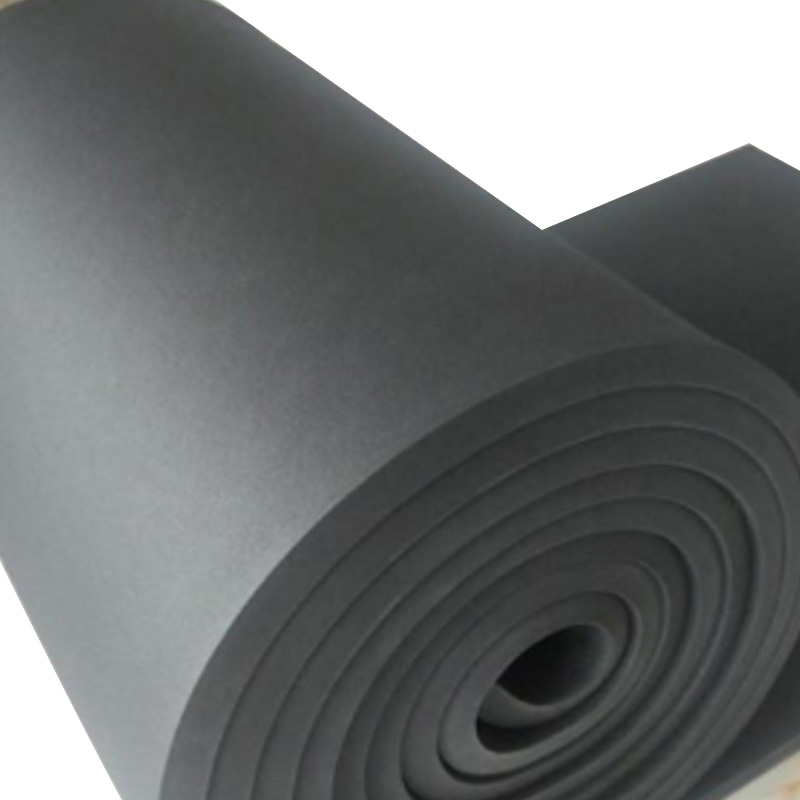

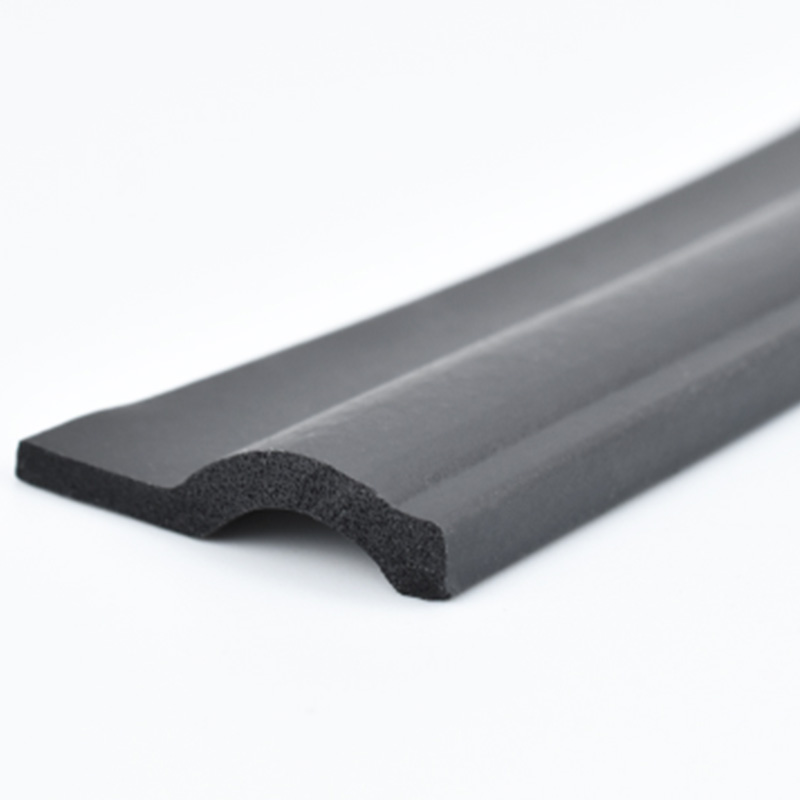

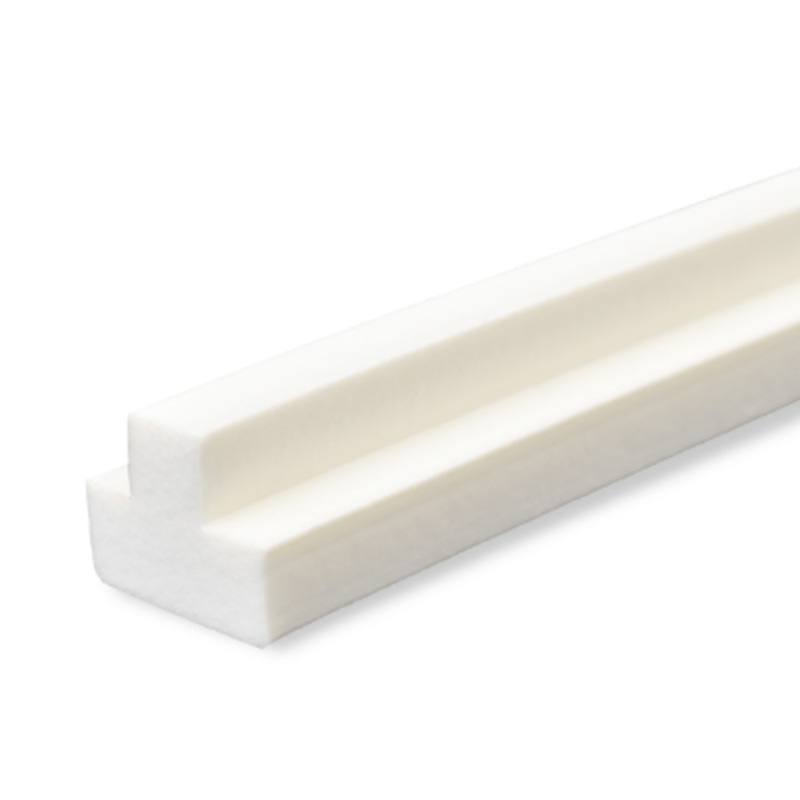

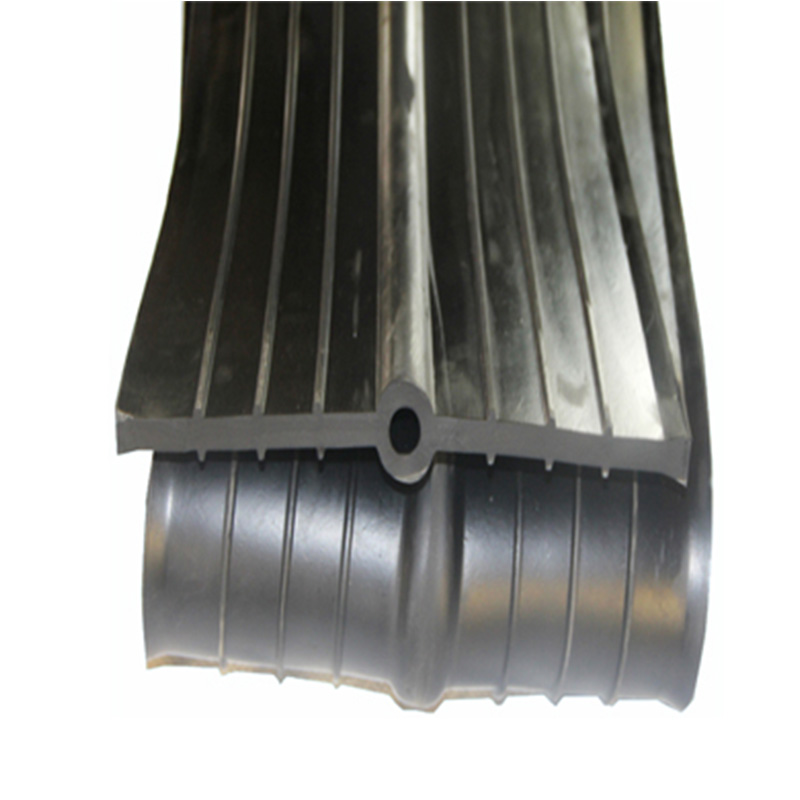

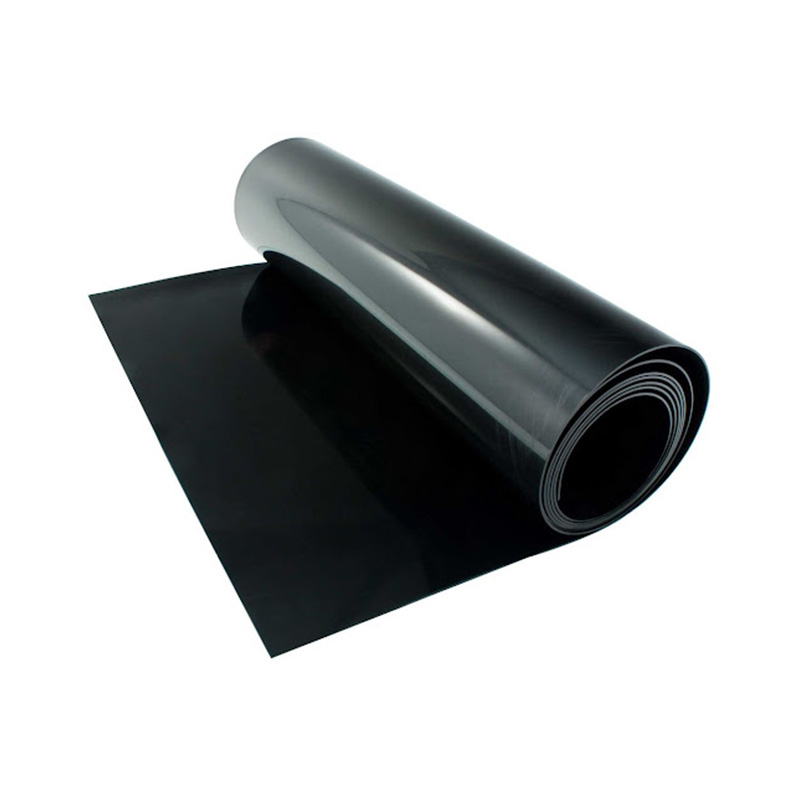

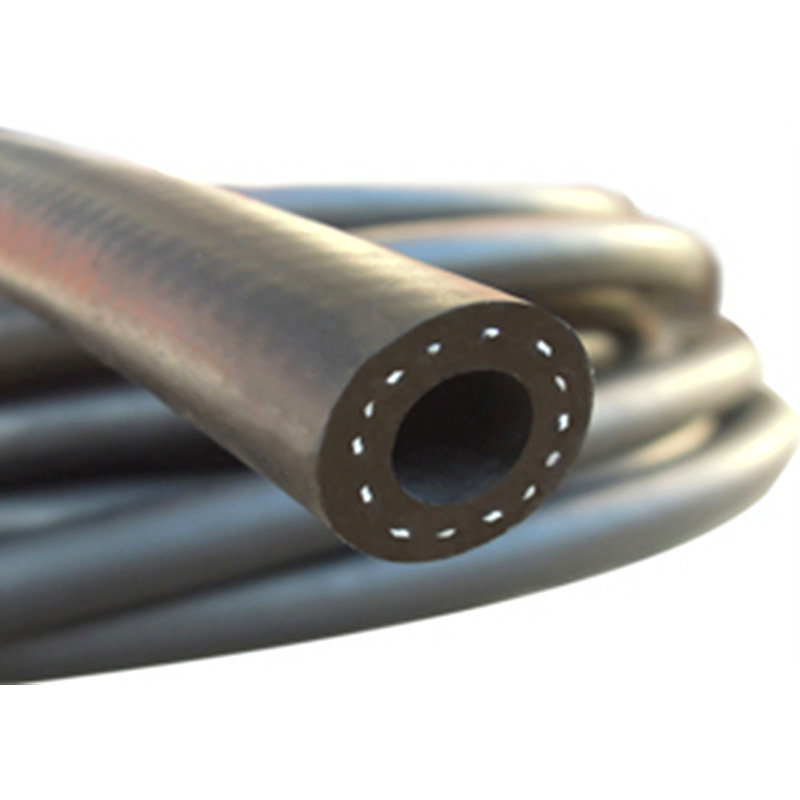

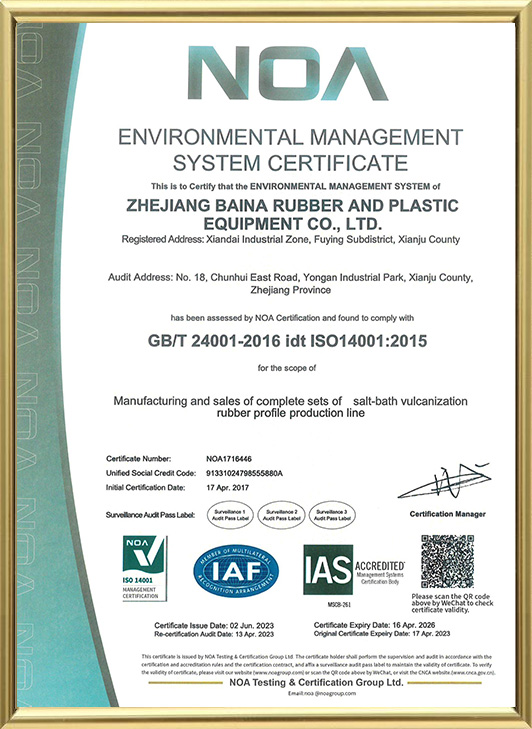

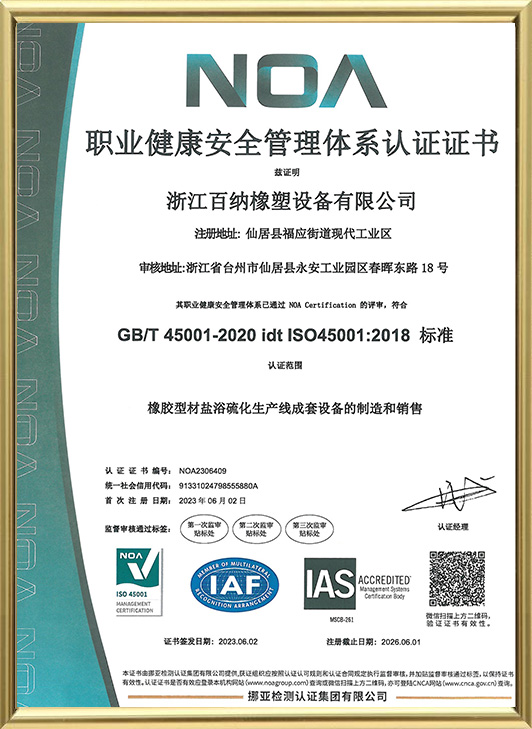

Zhejiang Baina Rubber & Plastic Equipment Co.,Ltd.is a Sale Rubber Single Extrusion And Microwave Curing Production Line Supplier. The main products are rubber extruder, rubber co-extrusion production line, rubber salt bath (LCM) production line, rubber and plastic air-conditioning insulation pipe vulcanisation production line, steel edge rubber water belt vulcanisation production line, silicone vulcanisation production line and other rubber and rubber products. Plastic equipment and high-grade rubber products such as automobile air-conditioning hoses, assemblies, sanitary hoses, braided hoses, rubber seals and low-density EPDM foam products.

FROM THE BLOG

Here to find the latest company and industry news and learn more professional product knowledge.

English

English 中文简体

中文简体 русский

русский