-

Key Components of a Typical Rubber Extrusion Production Line

Rubber extrusion is a widely used method for manufacturing continuous rubber profiles such as hoses, seals, weather strips, and tubing. The ...

-

The Production of EPDM Extruder

The production of EPDM extruders is a vital aspect of the manufacturing industry, particularly in sectors where rubber components are crucia...

-

The Historical Development of Rubber Extruder Machines

The rubber extruder machine plays a foundational role in the rubber processing industry, serving as a vital tool for shaping raw rubber into...

-

The Complete Rubber Extrusion Production Line: Key Components and Their Functions

The rubber extrusion production line plays a crucial role in modern manufacturing, particularly in industries that require the production of...

- Production Line Series

- Rubber Extruders Series

- Auxiliary Equipment Series

- Environmental Protection Series

We’re a reliable partner that shapes our expertise into success for your project.

Contact UsAuxiliary Equipment Supplier

-

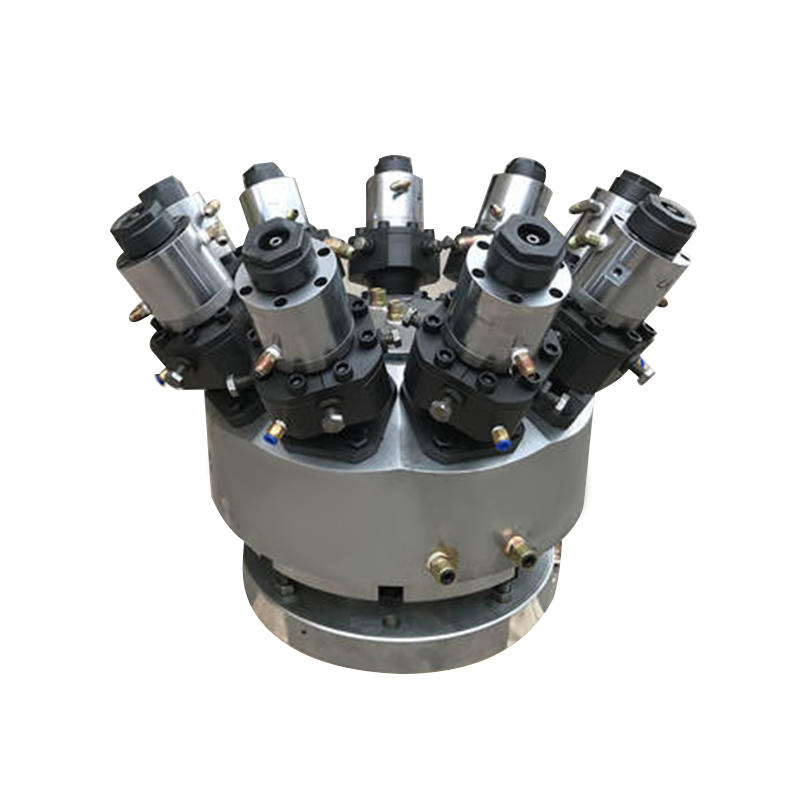

One Out Of Six Hose Head

-

Rubber Seal Strip Punching Machine

-

Rubber Strip Collector

-

Hard Strip Tracking Cutter

-

Film Cooling Line

-

Coating Flocking System

-

Hose Cutting Machine

-

Steel Belt Preform Machine

-

Steel Belt(Wire) Storage Rack

-

Steel Belt(Wire) Unreeling Machine

-

Steel Belt(Steel Wire)Unreeling Machine, Storage Rack

-

Composite Strip Molding Machine

Established in 1998 with a total investment of 120 million RMB, Zhejiang Baina Rubber & Plastic Equipment Co., Ltd is a China Auxiliary Equipment Series Manufacturer and Auxiliary Equipment Series Factory, and it is also Zhejiang Science and Technology SMEs, and municipal innovation pilot enterprises. The company is located in Modern Industrial Park of Xianju County, which covers an area of 90 acres and a construction area of more than 80,000 square meters. It is also conveniently located adjacent to the 35 Provincial Highway and the Taijin Expressway.

FROM THE BLOG

Find the company and industry news and learn more professional product knowledge.

Rubber Auxiliary Machines are an integral part of the rubber manufacturing process. They are specialized equipment designed to support and enhance the primary rubber processing machinery, ensuring the production of high-quality rubber products with efficiency and precision. Here's a detailed look at the role of rubber auxiliary machines:

1. Material Preparation: Before rubber can be processed, it must be prepared. Auxiliary machines such as mills, mixers, and calenders are used to mix raw rubber with various chemicals, fillers, and other materials to create a uniform compound. This process is crucial for achieving the desired properties in the final product.

2. Compounding: Rubber auxiliary machines play a significant role in the compounding process, where different ingredients are combined to form a rubber compound with specific characteristics. This can include the use of internal mixers, which are essential for blending and dispersing additives evenly throughout the rubber.

3. Extrusion: Extruders are a type of rubber auxiliary machine used to shape and size rubber compounds into continuous profiles. They are critical for producing items like hoses, seals, and other rubber profiles. The extrusion process can also be used to apply coatings or adhesives to other materials.

4. Curing: Curing is the process of vulcanizing rubber, which involves the application of heat and/or chemicals to harden the rubber compound. Auxiliary machines such as curing presses and autoclaves are used to apply the necessary conditions for curing, ensuring the rubber reaches its final, stable form.

5. Molding: Rubber auxiliary machines are also used in molding processes, where rubber compounds are shaped into specific forms. This can include compression molding, transfer molding, and injection molding, each requiring different types of auxiliary equipment to facilitate the process.

Many Types Of Rubber And Plastic Machinery Auxiliary Equipment

There are many types of rubber and plastic machinery auxiliary equipment that are used to support and enhance the production process. These include:

Mixing equipment: Mixing equipment is used to blend raw rubber and plastic materials with additives, such as colorants, fillers, and curing agents, to create a homogeneous mixture for processing.

Cooling equipment: Cooling equipment, such as water tanks and cooling fans, is used to cool and solidify the extruded product as it exits the die.

Cutting equipment: Cutting equipment, such as knives and saws, is used to cut the extruded product into the desired length and shape.

Conveying equipment: Conveying equipment, such as belts and rollers, is used to transport raw materials and finished products between different stages of the production process.

Curing equipment: Curing equipment, such as autoclaves and vulcanizing presses, is used to cure and solidify rubber and plastic products.

Recycling equipment: Recycling equipment, such as shredders and granulators, is used to process scrap materials and waste products into reusable materials.

Testing equipment: Testing equipment, such as hardness testers and tensile testers, is used to test the properties and quality of rubber and plastic products.

Automation equipment: Automation equipment, such as robots and computer control systems, is used to automate various stages of the production process, improving efficiency and reducing labor costs.

Auxiliary equipment plays a crucial role in the rubber and plastic machinery industry, supporting and enhancing the production process and ensuring the quality and consistency of the products.

English

English 中文简体

中文简体 русский

русский