ND OLD MICROWAVE OVEN CHECK LIST

|

Old type

|

Disadvantage

|

New design

|

Advantage

|

|

Transformer voltage variation

|

The circuit is complicated, inconvenient to maintain, has a high failure rate, and the efficiency of microwave emission is low.

|

Variable pressure of oil cooled power supply

|

The structure is simple, easy to repair and not prone to failure, resulting in a 20 percent increase in microwave emission efficiency.

|

|

Straight in waveguide

|

The microwave is easily reflected back to the magnetron, causing damage to the magnetron

|

A water loaded ring device is added to the waveguide

|

Effectively absorbing reflected microwaves to avoid damage to the magnetron.

|

|

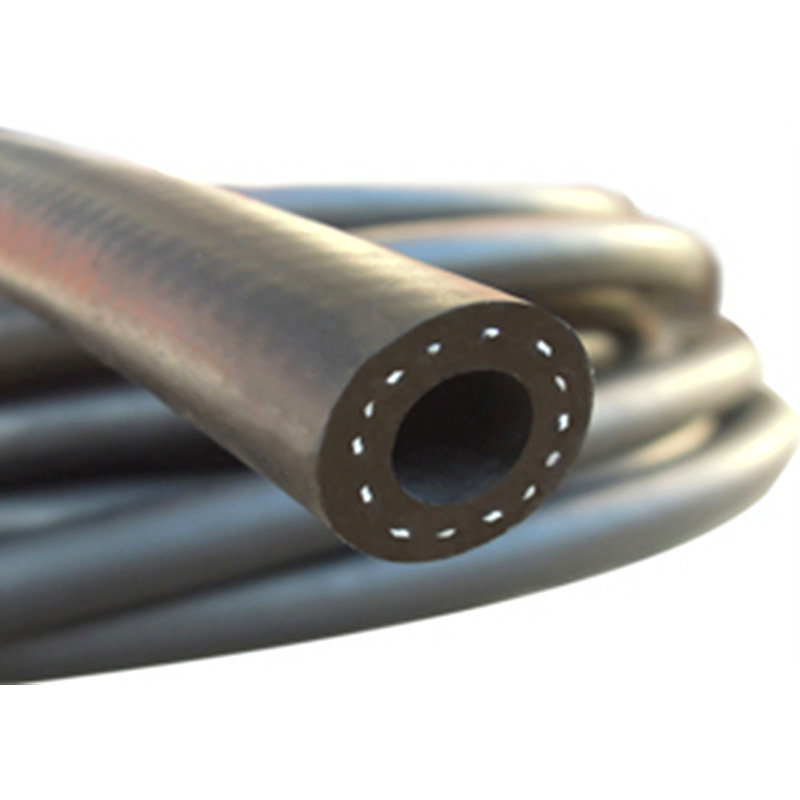

Waveguide tube homemade

|

The size accuracy is not enough, and it has some influence on the microwave efficiency.

|

Waveguide tube procurement with professional manufacturers

|

More precision, more use of microwave conduction

|

|

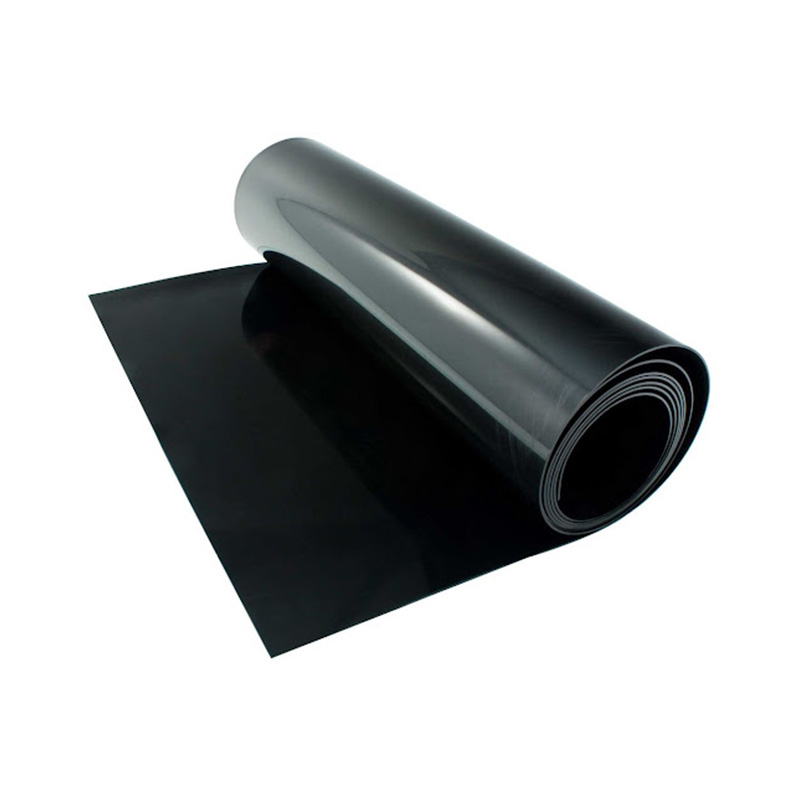

The cavity material is made of ordinary stainless steel

|

Absorb easily, which affects microwave efficiency

|

The use of a custom plate for the material of the cavity

|

It is not easy to absorb microwaves and improve microwave efficiency

|

|

Simple cavity structure

|

Microwave can not produce effective resonance in the cavity, which causes the wave to offset each other and redu

ces the microwave efficiency.

|

Design of the cavity according to the microwave emission law

|

The geometric design size is more beneficial to increase the number of resonant modes and to ensure a good match between the furnace cavity and the magnetron

|

|

Cavity waveguide layout

|

|

|

|

|

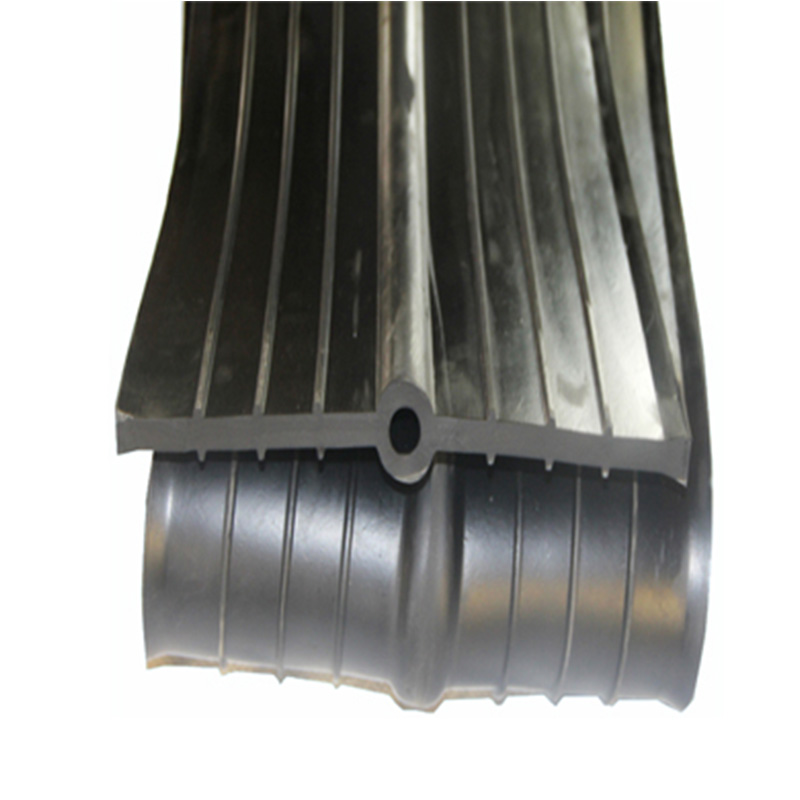

Short circuit ring + graphite resistance microwave

|

Unable to effectively stop the microwave leakage of the import and export

|

Import and export by short circuit ring + multi Zubo + SiC microwave barrier

|

Effectively blocking the microwave leakage of import and export

|

|

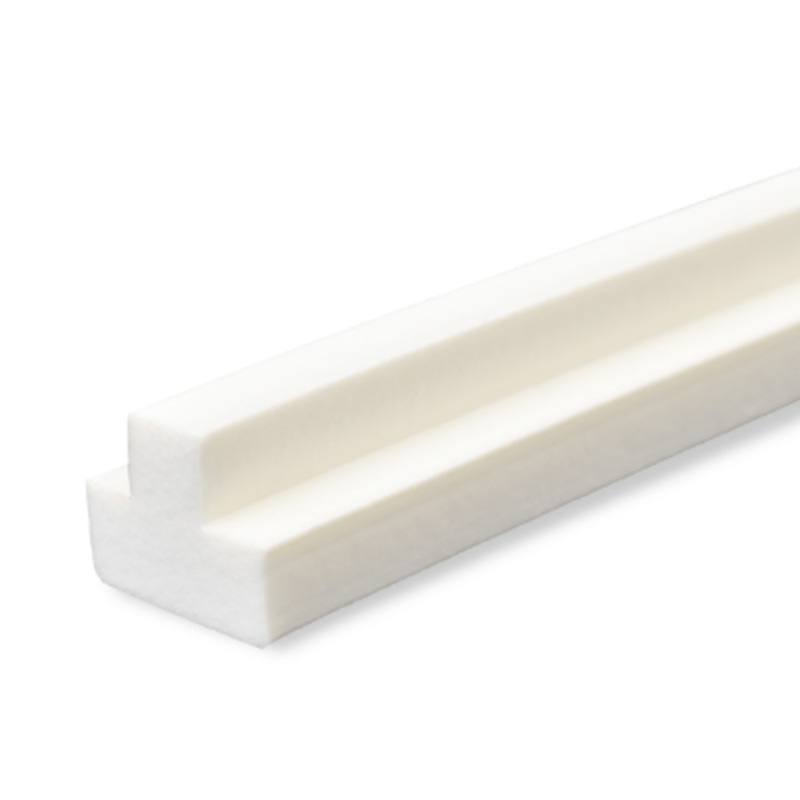

Metal mesh bar + asidealos strip is used in door cover leakage protection device

|

Microwave leakage prevention is not very ideal

|

Leak proof device for door cover using high waterfall silicone strip coated wire and wave retaining device

|

The effect of anti-microwave leakage is obvious

|

|

The total microwave efficiency is 35-50%

|

Microwave loss is excessive and wastes energy.

|

The overall microwave efficiency is 1.5 times higher than that on the original basis

|

High utilization rate, greater energy savings, increased production efficiency

|

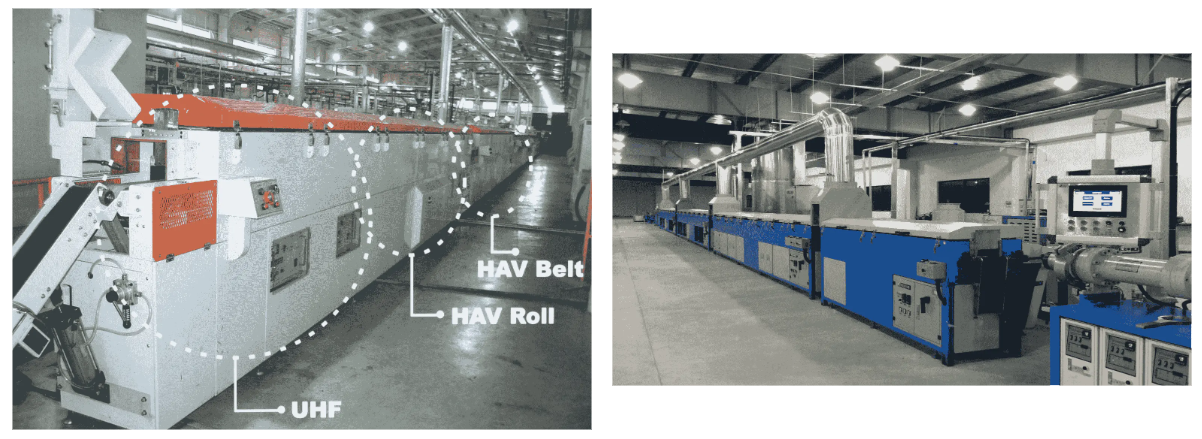

MICROWAVE VULCANIZATION PRODUCTION LINE AND PROCESS TECHNOLOGY

PRODUCT ADVANTAGE

Selection of industrial special waveguide tube accurate, more use of microwave conduction.

The material of the cavity is made of custom-made plate, which is not easy to absorb microwave and improves microwave efficiency.

The cavity is designed according to the law of microwave emission. The geometric design size is more conducive to increasing the number of resonance modes and ensuring a good match between the furnace cavity and magnetron.

Import and export use short-circuit ring + multi-segment resistance wave + silicon carbide resistance microwave, effectively stop the microwave leakage of import and export.

The anti-leakage device of door cover adopts high temperature resistant silicone strip coated wire+wave-blocking device, which has obvious anti-microwave leakage effect.

The shape frame adopts laser cutting iron plate folding type, which is beautiful and atmospheric.

The size of the internal structure is the same as that of the peers (6.8m). On this basis, it is extended to 8m, and the ideal vulcanization speed can be achieved by combining hot air with microwave more effectively. In addition, vulnerable parts of conveyor belt are also common with vulcanization equipment, which provides convenient conditions for customers to produce.

Microwave control system can achieve constant output of microwave power. Even if one group of microwave fails, it can also distribute its power to the other groups, so that the microwave output power can be constant and the effect of microwave on product vulcanization can be avoided.

THE PRODUCT FEATURES

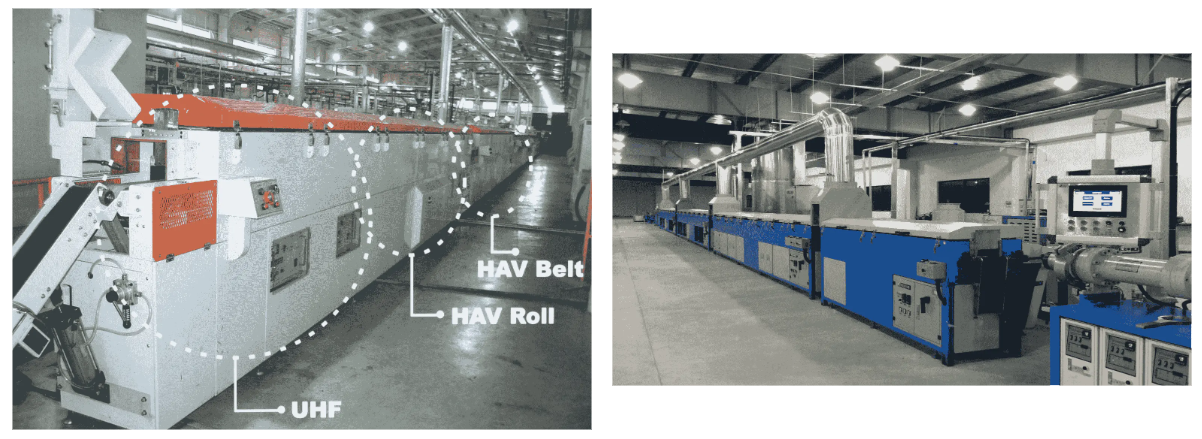

Rubber Microwave curing oven(UHF) Rubber Microwave vulcanization oven(UHF) Machine highlights

Effective machine lengths 8.9-10m

Natural gas heating LNG / LPG- according to Euronorm

Production speed up to 40m / min

Shock temperatures up to 500 °C

Microwave power up to 12 kW

High speed hot air zone

Separate roller and belt drive

Energy-efficient mode of operation

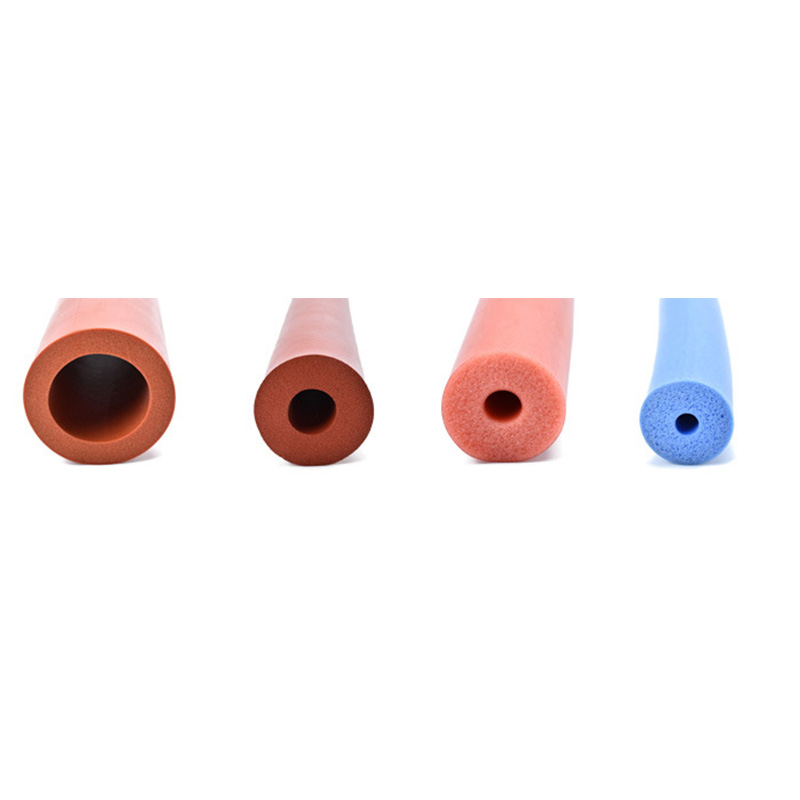

THREE(FOUR,FIVE)CO-EXTRUDED MICROWAVE VULCANIZATION EQUIPMENTS AND PROCESS TECHNOLOGY

English

English 中文简体

中文简体 русский

русский