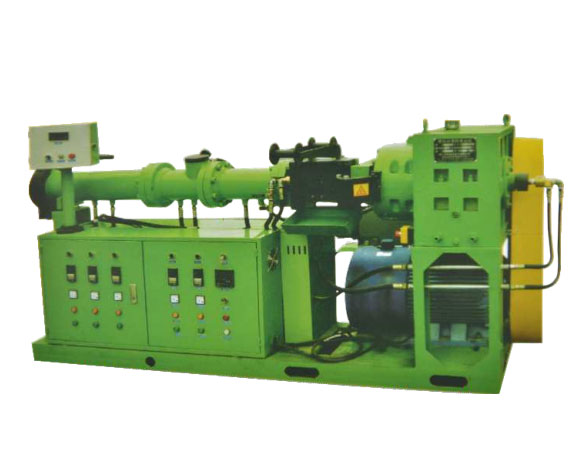

How to Use Rubber Extruder?

Due to the inconvenient opening of the rubber extruder, the degree of wear of the threaded elements and the bushing in the barrel can be found at any time, so that effective maintenance or replacement can be carried out, so that it will not be discovered when there is a problem with the extruded pro...

English

English 中文简体

中文简体 русский

русский