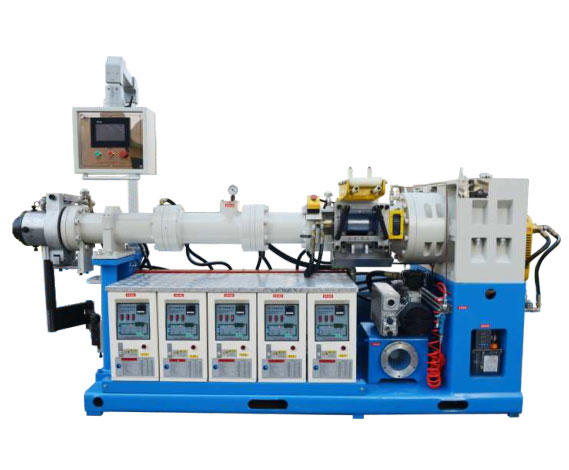

The Composition of the Extrusion System of The Rubber Extruder

Rubber extruder extrusion system includes: Screw, barrel, hopper, head, and mold, plastic is plasticized into a uniform melt through the extrusion system, and under the pressure established in this process, it is continuously extruded by the screw head. 1. Hopper: The bottom of the hopper is equippe...

English

English 中文简体

中文简体 русский

русский