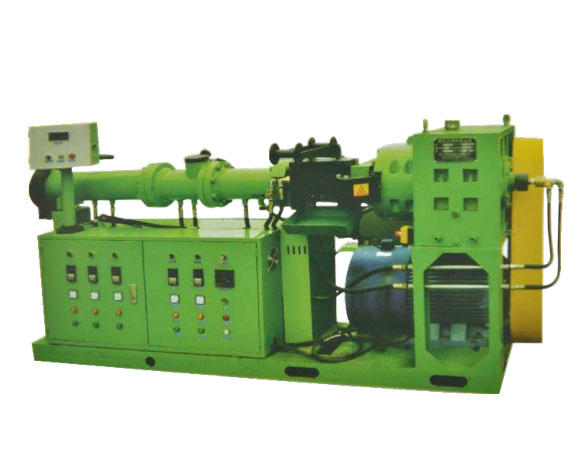

How Do Rubber Extruder Machine Start Working?

The rubber extrusion process of rubber extruder machine begins with a rubber compound being fed into an extruder. The material is fed into a feed hopper, which takes the material and feeds it into various flutes in a revolving screw. The screw will begin to carry the rubber forward into the die, wi...

English

English 中文简体

中文简体 русский

русский