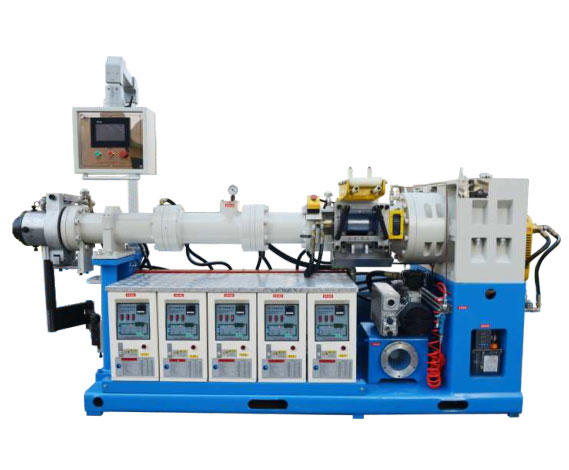

We Are Willing to Introduce Rubber Extruder Machine In Details

The rubber extruder plays a role of extrusion molding in the production of rubber products. Many rubber products are inseparable from the processing and production of rubber extruders. Our most common master is not used for sealing strips or shock-proof sealing strips. The application of EPDM seali...

English

English 中文简体

中文简体 русский

русский