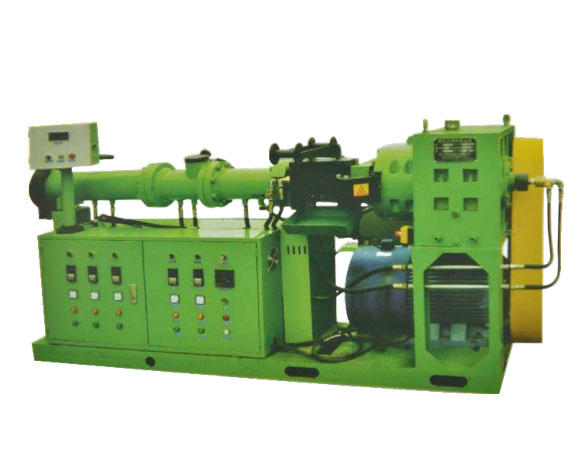

Working Process of Rubber Extruder

There are many types of rubber extruders. When purchasing rubber extruders, we should purchase them according to the purpose of the equipment. The configuration and design of different rubber extruders are different, but no matter what kind of rubber extruder, the working methods and processes in th...

English

English 中文简体

中文简体 русский

русский