-

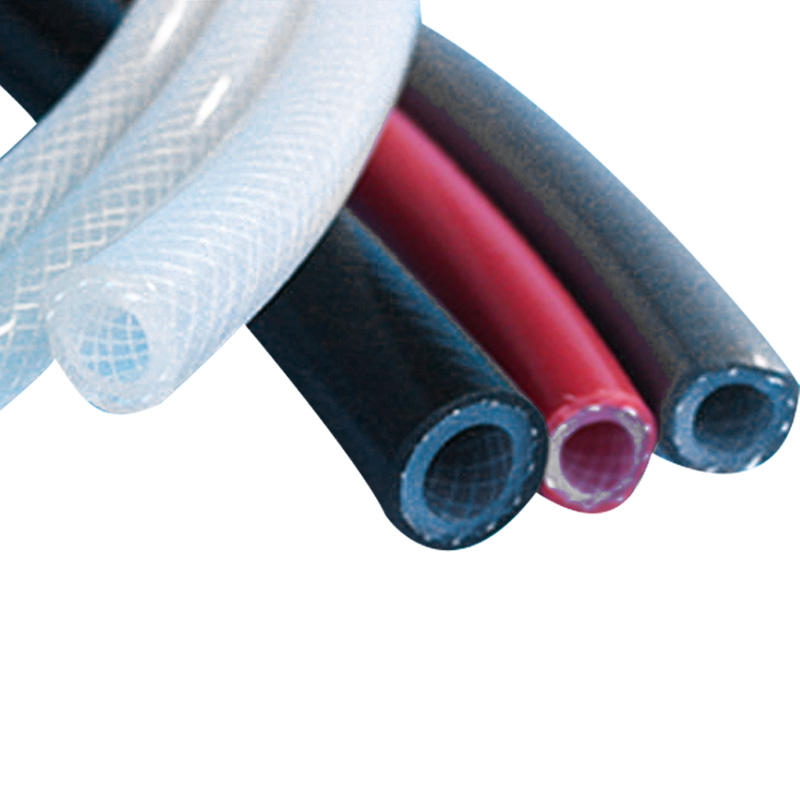

The Main Products of EPDM Extruders: Applications and Benefits

EPDM (Ethylene Propylene Diene Monomer) rubber is a versatile and durable synthetic material widely used in various industries. Known for it...

-

Why Is the Rubber Extruder Machine Widely Used?

The rubber extruder machine has become an indispensable tool in the modern manufacturing process, particularly in industries that produce ru...

-

Rubber Vulcanizing Machines: A Look into Technological Advancements

Rubber vulcanization is a key process in the production of rubber goods, as it transforms raw rubber into a durable and elastic material. Ce...

-

What is 50mm12D Rubber Extrude Machine Suitable For?

The 50mm12D Rubber Extrude Machine is an essential piece of equipment in the rubber manufacturing industry, designed to process and shape ru...

We’re a reliable partner that shapes our expertise into success for your project.

Contact UsRubber Production Line Manufacturer

-

Rubber 3 Co-Extrusion And Microwave Curing Production Line

-

Rubber Single Extrusion And Microwave Curing Production Line

-

150mm16D/20D Cold Feed Rubber Extruder

-

120mm16D/20D Extrude Machine

-

90mm Silicone Extrude Machine

-

90mm16D/20D Rubber Extrude Machine

-

50mm12D Rubber Extrude Machine

-

Preform Extrude Machine

-

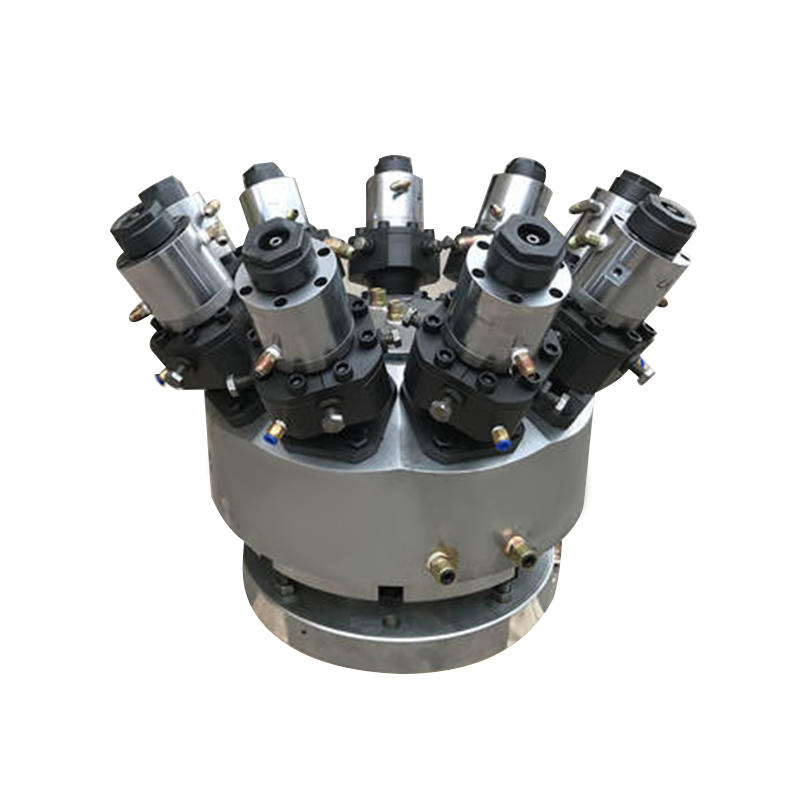

One Out Of Six Hose Head

-

Rubber Seal Strip Punching Machine

-

Rubber Strip Collector

-

Hard Strip Tracking Cutter

Established in 1998 with a total investment of 120 million RMB, Zhejiang Baina Rubber & Plastic Equipment Co., Ltd is a Rubber Production Line Manufacturer and Rubber Co-extrusion Production Line Company, and it is also Zhejiang Science and Technology SMEs, and municipal innovation pilot enterprises. The company is located in Modern Industrial Park of Xianju County, which covers an area of 90 acres and a construction area of more than 80,000 square meters. It is also conveniently located adjacent to the 35 Provincial Highway and the Taijin Expressway.

FROM THE BLOG

Find the company and industry news and learn more professional product knowledge.

What Is Included In Rubber And Plastic Machinery Equipment

Rubber and plastic machinery equipment are used to manufacture various rubber and plastic products, including pipes, tubes, sheets, bottles, containers, packaging materials, and more. The specific equipment included in rubber and plastic machinery can vary depending on the product being produced and the manufacturing process, but some common types of machinery and equipment include:

Extruders: These machines are used to produce continuous lengths of plastic or rubber material by forcing the material through a die.

Injection molding machines: These machines are used to manufacture plastic parts by injecting molten plastic into a mold.

Blow molding machines: These machines are used to produce plastic bottles, containers, and other hollow objects by inflating a heated plastic tube in a mold.

Calendars: These machines are used to produce sheets or films of plastic or rubber by passing the material through a set of rollers.

Compression molding machines: These machines are used to manufacture rubber products by compressing a preheated rubber material into a mold.

Thermoforming machines: These machines are used to produce plastic products, such as trays, by heating a sheet of plastic and then molding it into the desired shape.

Mixing and blending equipment: These machines are used to mix and blend various materials, such as rubber compounds, to achieve the desired properties.

Cutting and trimming equipment: These machines are used to cut and trim plastic and rubber products to the desired size and shape.

Testing and inspection equipment: These machines are used to test and inspect the quality and properties of rubber and plastic products, such as tensile strength, hardness, and durability.

What Kind Of Characteristics Do Rubber Products Usually Have

Rubber products can have a wide range of characteristics, depending on their intended use and the specific type of rubber material being used. However, some common characteristics of rubber products include:

Elasticity: Rubber materials have high elasticity, which allows them to stretch and return to their original shape.

Flexibility: Rubber materials are often flexible and can bend or twist without breaking.

Resistance to abrasion: Rubber materials are typically resistant to abrasion, which makes them suitable for use in applications where wear and tear is a concern.

Resilience: Rubber materials have high resilience, meaning they can absorb energy and bounce back without being permanently deformed.

Water resistance: Many types of rubber are water-resistant or even waterproof, making them ideal for use in applications where exposure to moisture is a concern.

Chemical resistance: Some types of rubber are highly resistant to chemicals, making them suitable for use in industrial applications where exposure to harsh chemicals is a concern.

Electrical insulation: Rubber materials can be excellent electrical insulators, making them useful for applications where electrical conductivity needs to be avoided.

Low-temperature resistance: Some types of rubber are able to maintain their properties even at very low temperatures, making them useful for applications in cold environments.

Noise and vibration reduction: Rubber materials can be effective at reducing noise and vibration, making them useful for applications where noise or vibration is a concern.

English

English 中文简体

中文简体 русский

русский